In various ways we invest in ‘green ways of working’ to reduce our carbon footprint as much as possible. To achieve this, we work closely with an expert in the field of integrated sustainability, who advises us and keeps us on our toes.

Our sustainable way of working consists of many different elements:

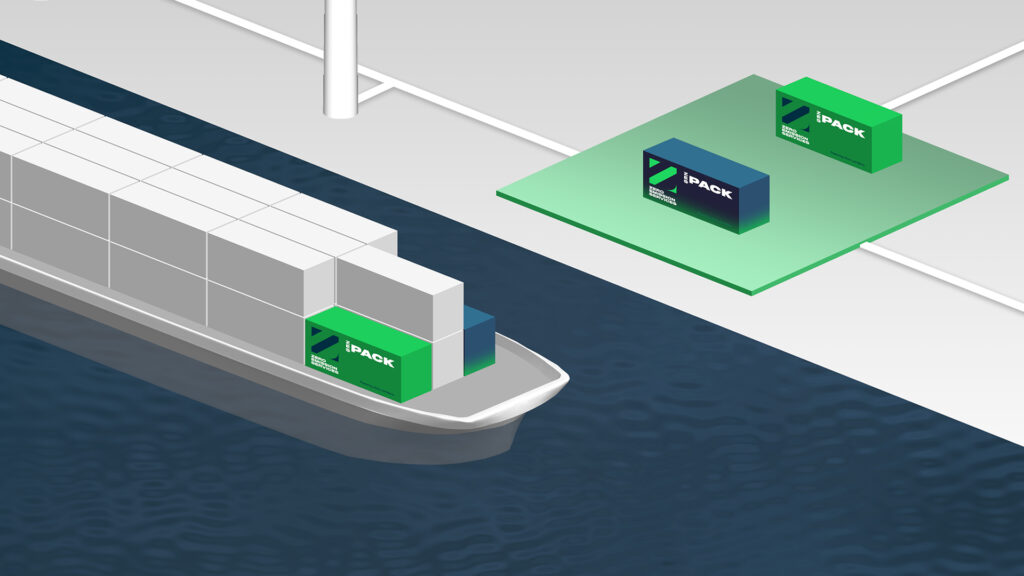

Consolidating inbound flows

Our unique location, immediately bordering the inland terminal, makes it possible to transport import containers from the seaports to ‘s-Hertogenbosch using hybrid inland vessels. This transition from road to waterways saves many truck movements and avoids traffic congestion. Containers for the ‘s-Hertogenbosch region are loaded on one barge and arrive at the terminal in accordance with a fixed sailing schedule. The consolidation of these flows on one hybrid inland vessel already reduces our energy consumption and CO2 emissions by 40%. When, in the near future, these vessels will be fully electric, the CO2 emissions will be zero. We are currently working on a tool for our customers, to provide insight in our current CO2 emissions. With this we hope to convince even more importers to make the sustainable transition from road to waterway.

Consolidating outbound flows

By continuously monitoring and aligning the logistics processes of our customers, we can regularly create attractive transport combinations. Goods of customers going to the same geographical destination can often share a container or a truck. The bundling of these different ‘flows of goods’ is efficient, cost-saving and sustainable. Here too, we like to think along with our customers and present them with proposals for improvement.

Sustainable last mile

Our multi-user warehouse in ‘s-Hertogenbosch, with its additional logistics facilities, is located next to the quay of the BCTN inland terminal. This makes it possible to place the containers from the ship, using a reach stacker, directly in front of our especially designed loading docks. These containers do not first have to be loaded onto a truck and transferred by public road. The last bit of transport to the warehouse (the last mile) is exceptionally short and very sustainable.

Making buildings more sustainable

At an early stage, most buildings at our SMART HUB have been fitted out with LED lighting and have solar panels on the roofs. We have also intensively looked at the various installations and the heat distribution in our warehouses. By involving the people on the work floor, we obtained a clear picture which working areas should have a comfortable temperature and which storage areas could do with a few degrees lower. Energy efficient heating panels have now been installed above the working places where people are stationary.